Everything posted by TourSpecGolfer

-

The New SEVEN CB

-

Benock World has Arrived!

Its a no-brainer what Jun-Okudas favorite Iron set is...

-

Benock World has Arrived!

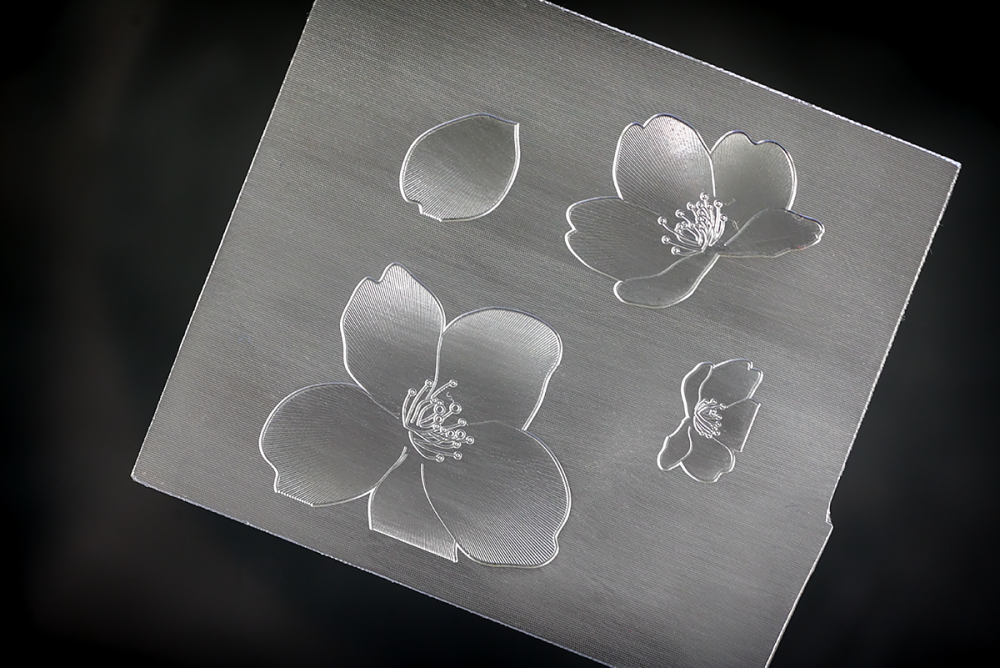

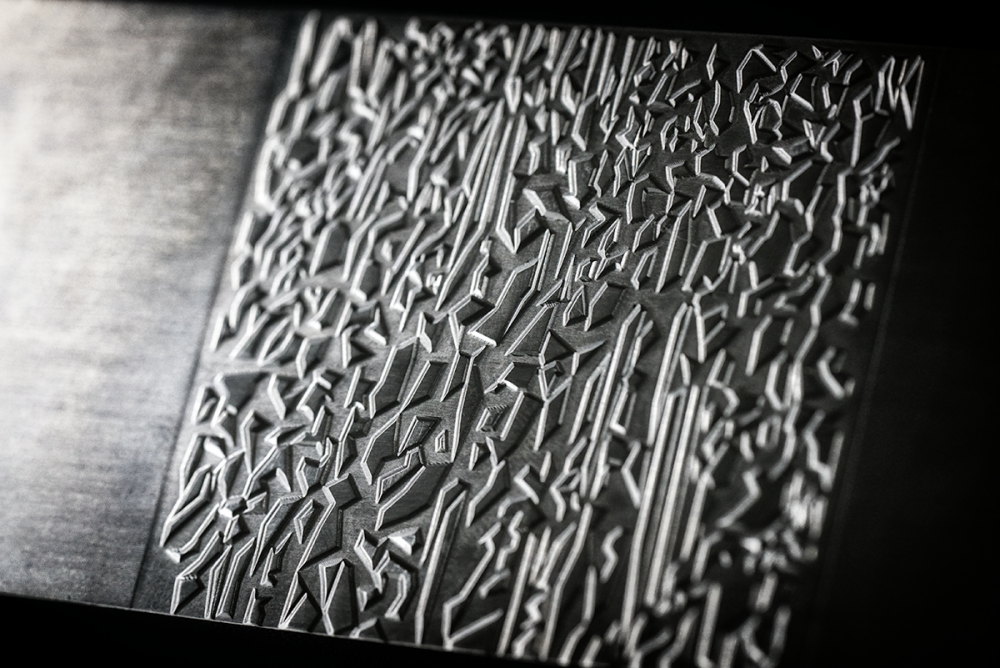

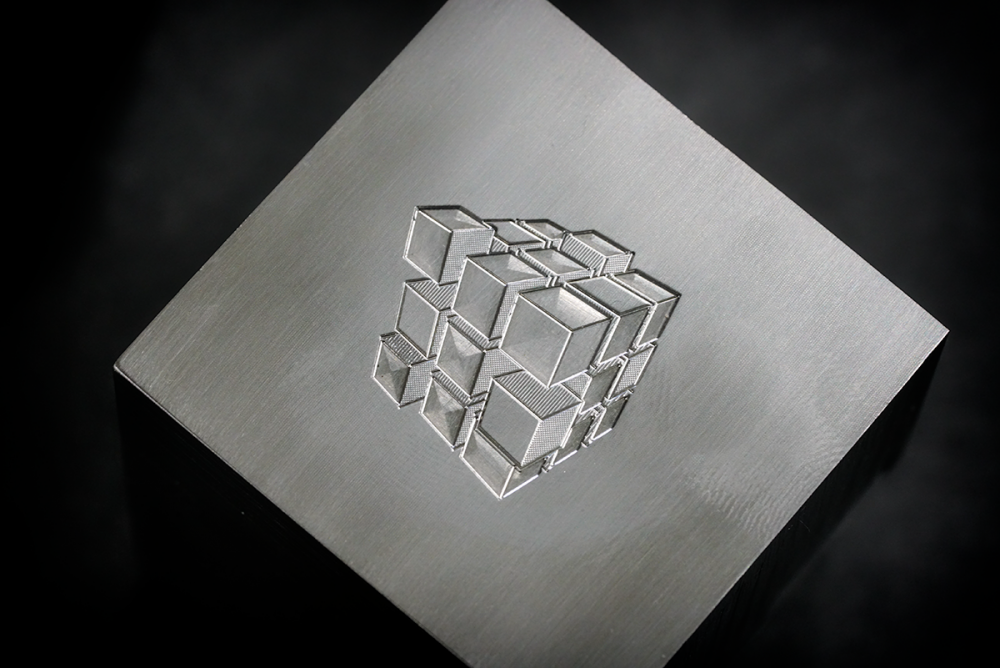

Micro Milling is a big deal, when you perform larger milling using a larger diameter milling bit, it creates higher levels of residual stress in the metal material. The material will become susceptible to effects of aging. When milling is performed in small amount at a time at higher speeds, there is less accumulation of residual stress on the material. In particular, for the face milling, using the more traditional face mill or flat-end mil processes it is actually harder to achieve precise flatness. We make thin mills using smaller ball end mill at higher speeds to increase the flatness. Just look at his work:

-

Benock World has Arrived!

-

Benock World has Arrived!

Okuda-san has told me there is a difference in the materials he uses. The suppliers from Japan he deals with do not sell impure materials. He says even in Japan many materials are tainted or recycled product. He says outside of Japan it's even worse. Why is 316L better? There are diverse classifications of Stainless Steel Alloy. For producing putter heads from ingot material, SUS303 is among the most popular material used. SUS303 a Stainless Steel Alloy based on the popular SUS304 but with increased Sulfur and Phosphorous additives. Increased amounts of Sulfur and Phosphorous additives make it easier to mill. (It is softer but less gummy/sticky) SUS316L compared to SUS304 have increased the Nickel content from 8% to 12% and added Molybdenum and also decreased the Carbon content from 0.8% to 0.3%. Because of this composition, SUS316L has better resistance to corrosion, heat and is softer. However, higher heat resistance makes milling significantly challenging, thus requiring specific milling techniques.

-

j-beam driver heads......,

I am an aggressive tempo/transition player with an over the top issue and I hit balls too high with way too much spin. JBeam ZY-11 has been my savior especially with a 7D or AAA. The lower trajectory and spin help me a ton. that said I have tried many shafts in these heads and some of them make this driver un-hittable and too low. Where am i going with this? I suggest trying several shafts with a new head before getting rid of it.

-

Benock World has Arrived!

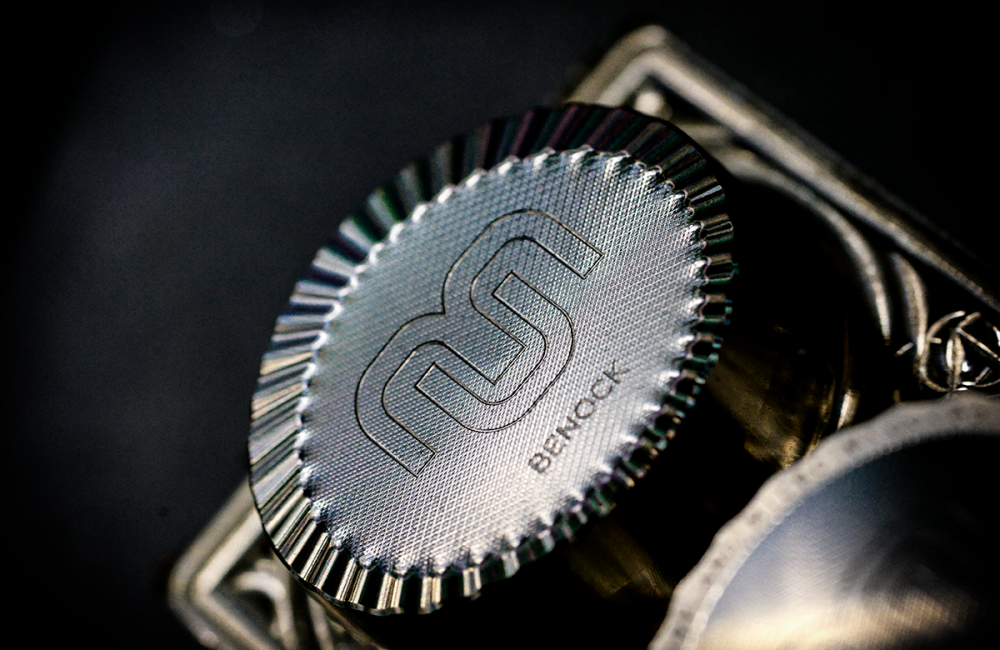

Ok so how it works is there are base model putters that run $1200 usd and they are now listed in the TSG Proshop. Most people will buy it this way but there is also the ability to create your own. Benock offers endless custom options to choose from even changes to the design itself including the neck. In fact you can custom create your own custom options even face milling or complicated art work. For custom requests you must email me [email protected] Everything is micro-milled. This isn't like Bettinardi or Scotty or Lamb or anyone else how they heat and bend necks or polish the edges by hand. This is a level above all and it's a tangible difference that you can observe in hand. Mr Okuda knows more than anyone I have ever met about materials and milling TSG will uncover much of this in coming months as well as more information about his partner NS Tool a company responsible for creating some of the absolute best products in many other industries as well. ( Cannon, Nikon, and Sony Lenses! ) just to name a few. The level of precision is astounding and unheard of in putters. Because Benock putter heads have been micro-milled with added considerations, they are able to achieve highly precise positioning of the CG relative to the center axis of the shaft. You know the game has changed when a customer can choose: * Balance Angle CG Distance CG Depth CG Height Pull Angle Milled Lie/Loft (not bent) We know the game has changed when in-house custom cad can be done at the individuals request with and manufactured in 1 month. Please correct me if I am arong but from what I understand Cameron just got their first 5-Axis milling machine to create rounded edges without hand polishing and only their best Circle T" M"asterful putters have this. Benock has five 5-Axis machines and these are extremely different to the ones other putter manufacturers use. He is also using the very finest end mills german controllers and Italian software.

-

Benock World has Arrived!

FOR IMMEDIATE RELEASE Next generation ultra precision CNC milled putters to hit US shores. Benock ultra precision CNC micro-milled putters available now to North American golf enthusiasts Kirkland, Washington – December 2017 Benock putters, an established high-end custom putter manufacturer from Kyoto, Japan today announced it would be introducing their latest lineup of customizable, ultra-precision CNC micro-milled putters to the US market. The company, known widely in the Japanese market for their unique “balance angle method” approach to custom putter fitting as well as highly advanced, state of the art CNC micro milling manufacturing process, will distribute their putter products thru TourSpecGolf, specialists in delivering premium Japanese golf equipment to enthusiasts globally. Benock has been manufacturing custom CNC milled putters for the most demanding putter connoisseurs in Japan. Benock’s design and manufacturing process are all done under one roof starting from the design of the heads by founder Jun Okuda himself followed by in-house CNC programming to carefully but strategically place CGs in specific locations to create optimal stroke performance. Their advanced CNC micro milling utilizes technique to minimize accumulation of stress to the ingot SUS303 or SUS316L material while achieving the tight tolerance levels that do not change with time. Benock founder and President Jun Okuda says “When the putter is designed to match a player’s natural stroke, the ball will roll straight to where it is aimed and over time will help make a player’s stroke more consistent. “ Benock hopes their customers will be filled with a sense of pride owning a personalized putter of the highest quality and precise spec. About Benock Putters Found in 1999 by Jun Okuda, the company was initially started with manufacturing of metal molds used to make cell phone parts. After 10 years in the metal mold business, the company starts developing putters applying the advanced milling techniques developed thru the metal mold business. In 2011, the company starts to focus on sales of their ultra precision CNC milled putters. By 2013, Benock has transitioned to exclusively manufacture and sales of putter products. Benock putters are manufactured using advanced CNC micro milling techniques to produce putters that are best in the world in quality as well as performance. Combined with their unique putter fitting methodology have quickly reached the pinnacle of high-end boutique putter brand in Japan. Please visit www.benockgolf.com

-

The ST is Back in Stock!

These retail for 225 We are taking orders now and shipping now. It was just added to the TSG Pro Shop - https://www.tourspecgolf.com/seven-st-wedge.html Yes they are conforming grooves but we will likely not send these into the R&A/USGA. RC6150s do have a nice shape. I also think you would enjoy the A-Grind V2.

-

The ST is Back in Stock!

Full skinny in the blog. You guys made this happen. I was never going to release these. Thank you because they are selling well. Introducing the SEVEN ST wedge – 2 years in the making. Initially, SEVEN decided against releasing the ST in favor of moving to full CNC manufacturing like the SEVEN CB and MCB irons. These heads collected dust in the corner of my design studio (garage) until one day I decided to sell off the prototypes. It was full steam ahead on the CNC wedges until a month or two later customers who purchased the ST wrote back to me how amazing they were. These are total wedge connoisseurs saying things like “this is the best-shaped wedge I’ve ever owned” and “the softest feeling wedges I have ever tried” and “these grinds do everything well” and finally my favorite “these spin like nothing else.” The praises were flowing, what should I do? We created these wedges using the same manufacturers as some of the wedges we idolize here on TSG. There was the Crazy Toyoshima wedge which grew a cult following of its own as one of the best boutique wedges available then became difficult to keep in stock. We also felt influence from the Sky Dream Jump 115 Forged Proto which had a micro-milled face incredibly fine and computer-milled grooves for perfect depth, sharpness, shape and spin consistency. Finally, there was the Yururi Gekku Wedge which is still to this day the best selling wedge on our website ever. Everyone loves the Yururi for its soft feel and spin and especially enjoyed its raw grain look. Take all 3 of these wedges and combine them into one and you will understand what this new SEVEN ST Wedge is. The shape of the Toyoshima, the spin of the SDJ Proto, and feel of the Yururi Gekku. Nuff Said… So this is part hand-made, and part computer milled. Some would say it’s the best of both worlds. If your wedges face and grooves are not full CNC milled there is a chance it isn’t flat, and there are multiple inconsistencies on the face be it uneven groove depth or curvature of the face and even dull grooves to start with. The ST features a teardrop silhouette which will appeal to the traditionalist players alike. The head is very compact and looks highly versatile which should please the most demanding wedge addict. It has the small hand-made touches and variations between heads making them traditional yet with a modern face. What took the longest was getting the fine milling right, its super fine almost so tight you can hardly see it in our photos. These heads are forged of Japanese S15C, so they are very soft. The standard version is in black boron; this is not black oxide. We selected black boron for its look and that it is a little more durable than the oxide. We are also going to be producing a smooth version which is like most other wedges out there. So really all you need to remember is three lofts available 51/57/61 in a smooth body or grain body. Black boron is the standard finish, we can also offer them to you completely void of any finish as RAW for the same price, or we can apply a custom finish for a small upcharge. Custom paint fill is no problem and included. Yes, we do custom builds as well, In my set, I am playing Fujikura MCI Wedge MILD shafts, and they are fantastic, the head’s weight is ideal, spin control is imo better than steel, and it makes the club feel even better. The 57 and 61 have very similar grinds with a killed leading edge for the steep swinger and enough trail/heel/toe relief to open it up. The 52 which is likely to see more full swings has a grind that supports the approach you want to make. Thank you for reading! And we hope you are able to get what you need before these sell out.

-

Anyone ever hear of Wood Bros Putters? Japanese Hand Forged.

I've never heard of dave before, but once you mention swordmaker in Japanese golf, it's a red flag. The sword thing is something I harp on. Same deal with other U.S distributors of Japanese brands using the ancient sword angle. It fools a lot of people but pots and pans would be more accurate when talking about Himeji. These brands have nothing to do with swords, yet it has been in their marketing for years. Foreign distributors of many Japanese golf brands regurgitate this to others. So yes It's a stretch to say Japanese swords are related to the golf industry. I am not browsing websites for my info or watching brand videos. I lived in Japan 3 years, have been back more than 20 times for 1-3 months at a time. Every day I talk to multiple brands, we visit the best factories and are friends with golf historians. We know people at Mizuno who have been there for about 30 years possibly more. If you have a specific question, I can ask and get an answer. I would be happy to learn something new if I am wrong. My best guess is there is a disconnect between Dave and his colleagues in Japan. Also what is not explained is why these two hand bent putters are the same ones I can get. The only two choices available for hand bent putters I have seen in Japan. They are open model hand bent putters. They are not made like a sword but they are heated and bent. A tiny bit of hammering to move the metal. I have watched and video'd these being made in Ichikawa Japan. If he is your buddy just ask him who made these? Or what city they were made in?

-

Best "one flex only" shaft out there.

try tipping the shaft or installing a lower launching shaft.

-

Best "one flex only" shaft out there.

I use design tune single flex irons shafts on my MCBs. It took a little time to get used to but now they are dialed in.

-

Grandista RS-W

I do think the ferrule looks kinda cool

-

Wooden Dowels - Improve feel, yes or no?

Wooden dowels are nothing new. I have used percussion instrument transport material in its place. It's similar to tourstage turbo rubber. It weighs less, it dampens vibrations better, and its a soft rubber. A grip can soften feel as well, a shaft, finish, etc.. etc..

-

Best "one flex only" shaft out there.

talk about you sir. swing speed tempo & transition speed current shaft / model / flex? what you looking for in new shaft performance wise? say that and I can tell you if you should even play one of these and if so which one.

-

Grandista RS-W

No reveal these are several months old. While I really like grandista woods. I do not understand this one. I do know where it is made though. You never want to add weight to an already long hosel. This hosel is average or a little long. adding weight will yank your CG toward the heel not straight up and down like they say. The grooves and face are not CNC this means the face may not be flat. I see fluff and based on the new grandista irons they are going the open model adjustment route.

-

Anyone ever hear of Wood Bros Putters? Japanese Hand Forged.

I see 2 putters on that link. I know where both are made. In Ichikawa japan - sample place that made our Hizukuri. In fact, that is a version of the Hizukuri in one of his photos. Billet is heated and Crafter bends it to shape There is no actual layer folding being done like a sword and these guys have never made a sword before. That solves that.

-

Anyone ever hear of Wood Bros Putters? Japanese Hand Forged.

hand forged by a sword maker? I'm not sure I buy that. Hand forged club right here - http://blog.tourspecgolf.com/seven-hizukuri-proto-l/

-

YORO CRAFT show & tell.. Lets see them..

I miss the M-Stamps!

-

Miura handstamp...

No I dont.

-

Tyson Lamb

Very nice work. A brand built on Instagram and forums. You are buying his art and his branding and paying a premium for it. He is not using high-end cad software or controllers, he is not using top of the line 5 axis machines or tools nor does he need to due to the designs being very basic, you can get the same CNC setup in your garage for about 1500 bucks a month financed from Haas. Its just a matter of learning how to use it. He is not able to create a one off cad for the customer as benock is. Many lamb putters have a separate neck as well. Big no no in my book even for a $300 putter. His finishing work by hand and his attention to detail are beautiful. The putters do not have to be this limited. That is simply a marketing angle or a design flaw in the process. He can easily pump out all the heads he needs, its just a matter of finishing work, polishing edges, stamping and all the little cool stuff he does. He can put the same program into someone else's CNC machine to double his output with ease. He could purchase another machine to pump out double. He could hire someone to run the machine while he is busy with other things. if anyone has questions about putters let me know. I have made many and have many more coming. I know whats good it just depends on what you care about and want. Technology? - Benock Fitting Concept? - Benock Quality & Materials? - Benock Art Work? - Lamb Brand? - Cameron Market Buzz? - Lamb

-

Miura handstamp...

These are aftermarket. No idea, there are so many mod shops out now days.

-

VG3 Driver

- VG3 Driver

They are releasing much of it before the Japan Golf Show. - VG3 Driver