-

Can Offset be your friend?

Yeah, that PRGR test was pretty interesting especially how more offset led to lower ball flight. From a physics and engineering standpoint, it actually makes sense. When you add offset, the head's center of gravity sits farther behind the shaft. That promotes a bit more shaft lean at impact, which reduces dynamic loft and results in a lower launch. It also changes how the face rotates — the more offset, the slower the face closes, which can make it easier for some players to square it up, especially if their hands trail a bit through impact. Less offset, on the other hand, puts the CG more forward, which increases launch and makes the club more responsive — or “sensitive to timing,” as they say. But like you mentioned, that part really just comes down to getting used to it. More Offset = Lower launch, less spin, possibly tighter dispersion for some, easier to square for players with an out-to-in path or slower hands. Less Offset = Higher launch, higher peak height, more feedback on timing, preferred by better players who want to shape shots and keep face control front and center. So yeah, the lower flight from added offset isn’t just anecdotal — there’s a real mechanical reason behind it.

-

It doesn't get any more JDM than these! ( BRIDGESTONE MUGEN WEDGES )

The current biting spin from Bridgestone is really good. I play these now. not only are they made by Endo but they are just ever so slightly oversized which my game totally needs.

-

Miura TC-102, TC-202 look so much like RMXs

Ya know Miura is forged at Sasaki now. Yamaha's latest single piece forged is made at Endo. Thanks for posting Noboru! Just got back from Japan, gained 15lbs :)

-

The Diamana Red Board is Back!

Thanks for posting stew, you would probobly hit the clouds with this RED>

-

It doesn't get any more JDM than these! ( BRIDGESTONE MUGEN WEDGES )

brought theese in, shot pics and drop them here. I used to drool over these but today and especially once you hold them up close to any iron from SEVEN the difference is night and day in terms of golf specific milling capabilities. There are two types, these wedges run about 800 a pop or so. not worth it. one of my bags has the standard biting spin bridgey wedges and I love them! severely underrated IMO. my pics make these look better than they actually do in hand ;)

-

We are now selling Future Force!

wow! have not seen you around a while! good to see u. Is it Lee? sorry if I got that wrong anyway good to see you here. Me, Tatsuro, and the FF team have some drinking to do tonight. Was just with Tario the past two days :)

-

We are now selling Future Force!

My distributor for KYOEI and SEVEN in Taiwan started their own brand registered in the UK with a European design team and the brand is focused on the asia market... Yes kinda complicated but I love these guys and support them regardless and we are announcing the brand at the 2025 Japan Golf Fair this week! TourSpecGolf Golf BlogIntroducing Future Force Golf! - TourSpecGolf Golf BlogFutureForce Golf is a UK-based company incorporating European design and marketing to create performance-driven golf clubs tailored to Japan and the broader Asian market. Their focus on modern engi...

-

Takumi Japan's K1 Mold Irons with a Crazy Finish!

The finish is the alphamek black teflon with some laser etching and a polished satin. quite possibly the most sexy finish ever. For those of you who are unclear about the relationship of all the KYOEI brands: Takumi - factory president keisuke sakamoto's passion project KYOEI Golf - I design, own and operate this brand personally, its basically the same setup Miura Global has with Miura Giken. / KYOEI Golf has with KYOEI Factory Zestaim - sold to a guy in Korea, it was sold 4 years ago to Majesty Vega - started by the former president of KYOEI and sold to PGE in Europe Now you know. full scoop here - TourSpecGolf Golf BlogTakumi Japan Type T Iron - TourSpecGolf Golf BlogPowered by KYOEI When it comes to the KYOEI Golf factory in Ichikawa Japan there is a long history of brands that use their forgings as well as brands born from the Sakamoto family directly, brand...

-

is this site working again ?

Great Idea Steve! Will do that right now! Also on FB please sign up for the group Japanese Golf Clubs!

-

Guess Who Crawled Outta the Grave after 5 Years!?

Thanks Steve for dropping by! I'm back in Tokyo right now gonna post some JGF stuff here in the forum!

-

MY fairway woods ....

Just a solid all around FW, SYB is severely underrated! Those shafts! Only maniacs know if them!

-

TourSpecGolfer changed their profile photo

-

The Diamana Red Board is Back!

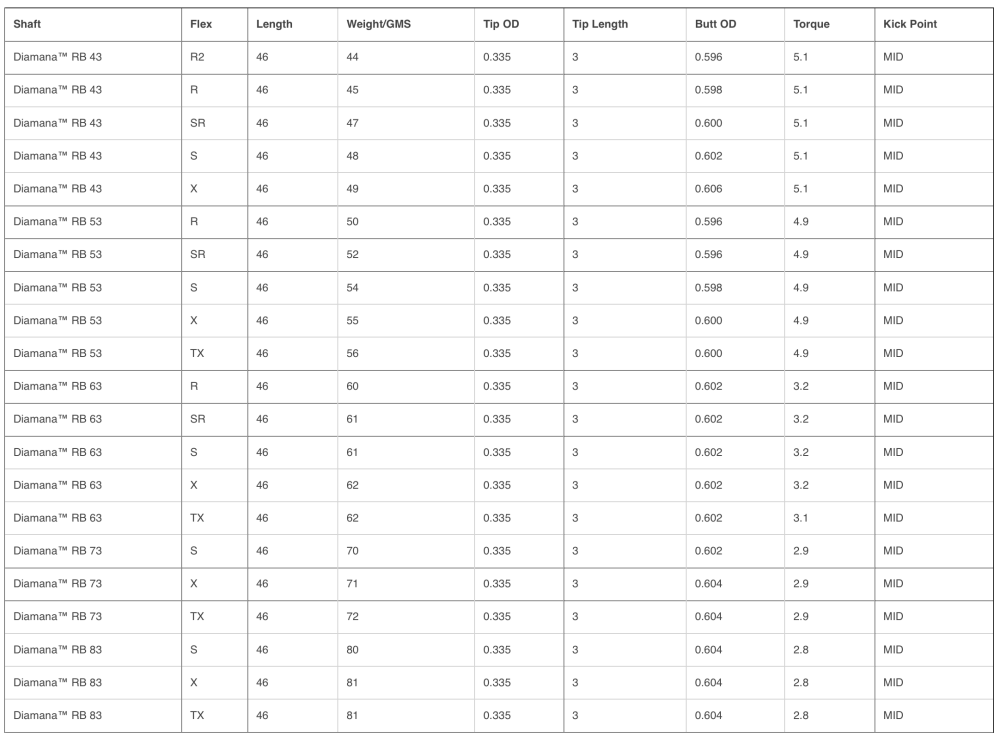

I haven't touched a Mitsubishi in ages but when one of the core models is updated it's worth noting. The blue board, white board, and red board fall into that category. Of the budget shafts I am playing Tour AD GC in my Bridgestone driver, but because I got the hook up and play the fancy stuff it's the basileius AAA that always hits my bag. That said for those of you who need a bit of lift and a smooth feel this red board is a consideration. This new Diamana Red Board is designed to give you a slightly higher launch than the BB model, making it easier to get the ball up without losing control. That means better carry, better distance, and more consistency. If you liked the previous Red Board, you’ll love that this version brings back that active tip section, helping generate a little more speed through the ball. The butt section is built with 80-ton DIALEAD Pitch Fiber, which helps with stability and energy transfer, so you’re not losing any power through the swing. Then there’s the high modulus 46-ton fiber in the angle plies, which keeps torque low without adding extra weight—basically, it helps prevent twisting while still feeling smooth. And to top it all off, the Xlink Tech™ Resin System increases the shaft’s strength and durability,

-

I've been playing these for a couple of months now...

So the new 258 CBP was just announced today officially. we got the skinny in the blog HERE But in my bag is a combo set of 241/242 with Tour AD 95's built to my spec from the factory. just great all around. equal to Srixon's better than Mizzys imo, of course not SEVEN SC level but they are forgiving and they aint ugly. playing the wedges too, they are a tad oversized but I need it. Got mugens on order. The new 258's are coming march and are the two piece option and in order of forgiveness 241/242+ and 258 CBP. lofts are nicely jacked at 44* which has become my new preference. Totally happy with the AD-95's so gonna stick with them.

-

Guess Who Crawled Outta the Grave after 5 Years!?

Hey you rowdy bunch of golf addicts, guess who decided to crawl out of the bunker after five years? Yep, it’s me, your long-lost forum overlord. Turns out I wasn’t dead just busy terrorizing golf courses and mourning my pathetic short game. I see the lights are still on here (thanks for paying the bills, by the way). I expected tumbleweeds and a few lost souls, but you guys kept this place alive color me impressed. Let’s crank this forum up to full throttle again, like we’re storming the 19th hole on a Friday night. Expect the usual chaos: over-the-top club obsessions, questionable swing advice, and a generous side of trash talk (the good kind, of course). So strap in, buttercups we’re making this forum great again! Post your rants, roast each other’s gear, and let’s party like we just holed a 60-foot putt. Feels good to be back. Now hold my drink! Wanna thank Cuistot for showing me the light!

-

Help needed / who made this

Carlton Matsui using KYOEI forgings.