Everything posted by TourSpecGolfer

-

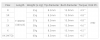

LOOP PROTOTYPE FW SIX Shaft Breakdown

Introducing the LOOP by Syncagraphite Prototype FW SIX Shaft designed specifically for fairway woods. The new FW SIX is made for better players who require better contact, more control, heavier weight. it's tip section is specially designed to help launch the ball up with no ballooning just a strong mid/high trajectory with a design emphasis on making better contact with fairway wood shots. It's tip section is slightly stiff, mid section is medium with a slightly stiff but section. The performance concept also promotes: - No ballooning - Reduction in back and side spin - Less toe down movement near impact - Stable high trajectory strong ball glight. - Heavier 68-70g shaft Available in 5 flex options that you can choose: ( SR , S , SX , X )

-

LOOP PROTOTYPE BW Shaft Breakdown

Here's one customers selection example: 93mph Swing Aggressive Tempo Aggressive Transition Avoid the Slice Promote a Draw So I was thinking an SR Flex HD would do the trick but after considering with LOOP it actually came out to the BW due to the tip design which trumped the aggressive tempo/transition which could be nullified by going up to S or SX in Flex. This is why our dual fittings are important it gives you an opinion from TSG as well as the Factory Manager at LOOP. This customer went with the LOOP BW SX Flex installed in a Baldo 568 Head and is extremely happy with the result. This person has purchased many previous shafts TRPX, Fujikura, Mitsubishi that did not work but finds this shaft to be the one that performs far better than any of them.

-

LOOP PROTOTYPE BW Shaft Breakdown

Introducing the LOOP by Syncagraphite Prototype BW Driver shaft - The new BW Shaft is designed for the smoother swinger from low handicap to average player that has a smooth transition and swing with little aggressive body movement. This shaft is one step softer than the HD model in the LOOP model line up. Deisgned with a new tip section technology that takes advantage of Syncagraphites UD (Uni-Directional) Materials, this tip structure is designed to help the average to smooth swinging player avoid the right side or slice with it's specific tip structure The BW shaft is ideal for a person who prefers a lighter weight shaft and plays their drivers longer in length 45.5" or more it has a stiff but section section with a softer flexing tip area his helps the player who dislikes the fade/slice and favors a draw. The structure concept is designed around for more carry and distance yet still reducing back and side spin while near impact there is less toe drooping. The tip section is strong yet soft with a forward kicking motion called super speed tip design. This Loop Prototype BW Driver Shaft is available in 5 Flex options which all above 51-54g in weight ( R, SR, S, SX ) All LOOP Shafts are Custom Install Only - Not Available Shaft Only. You May order a custom build from TSG via [email protected] or purchase the head and shaft from the proshop for a free install with custom specs in the memo box at checkout or you can send us your head for a professional installation to spec.

-

TSG Club Works | R9 TP Forged Copper + Satin/Blue

TSG Club Works has previously posted 3 different Taylormade R9TP Forged irons in the blog, the black boron w/ yellow, black mirror w/white, copper underlay + satin w/red and the final and last set we produced the copper underlay + blue paint. We produced 4 sets in total from used irons sourced in japan after the refinishing they are all in excellent condition not brand new but look pretty close and after testing these feel better at impact since the refinish over the factory finish. We have not listed any of these for sale yet, now that all 4 have been shown we will be adding to the TSG ProShop for immediate shipping, enjoy the pics of the copper underlayer + satin blue, by the way all of our finishes are done in Japan in this case it's NiCr Satin which can't even be done in the states due to EPA regulations.

-

SEVEN X SHINAGAWA BLADE!

The Red's are more forgiving, softer all over the face yet doesn't feel as good center and the Red2 is longer due to stronger lofts. My gamers for almost a year have been the SEVEN X Shinagawa's It's the better shape, look, feel in center and it acts as a true players blade I also prefer it's manufacturing over the RED2.

-

LOOP PROTOTYPE HD Shaft Breakdown

Introducing the LOOP by Syncagraphite Prototype HD Driver shaft - The new HD Shaft is designed for the faster swinger yet not as fast or aggressive a swinger as the Prototype CL model. Deisgned with a new tip section technology that takes advantage of Syncagraphites UD (Uni-Directional) Materials, this tip structure is designed to help the faster swinging player avoid the left side or a hook by keeping the tip section from twisting instead it pushes through the ball forward. The HD shaft has a stiff mid section with normal flexing tip area and butt end this helps the player who dislikes the draw and favors a fade and has an aggressive transition with smooth swing. The structure concept is designed around a lower ball flight and reducing back and side spin while near impact there is less toe drooping. It's produced using a double hold process which is an original technique by syncagraphite's factory. This Loop Prototype HD Driver Shaft is available in 5 Flex options which all above 55-60g in weight ( R, SR, S, SX, X, XX ) Due to the shaft structure and design players often have the perception the shaft is actually heavier than what the weight is. All LOOP Shafts are Custom Install Only - Not Available Shaft Only. Important - Before you comment read this thread : LOOP

-

Honma Beres IS-05 Forged Irons

IE is noticeably larger with more offset, even more forgiving and stronger lofts with lighter heads so basically for slower senior or female player.

-

Crazy SBi-02 Blades in Satin

For those asking about the gold finish version, pics here as you can see it's not entirely gold just the very center of the dip is something I've not seen done before.

-

SEVEN K1 in Black Mirror Finish

Not for SEVEN but I just confirmed the Master has a few lefty Newport 2 style blanks he is able to work his magic on, they are FE Carbon heads meaning they are soft and require a finish.

-

Honma Beres IS-05 Forged Irons

Run Down of the differences vs the IS-03 in the blog, pics right here. - Game improvement irons for the slower swinger/senior player/or faster swinging lady - Forged Body + Maraging Stainless face like a UT - vs the outgoing IS-03 they have increased face height & length by 1mm and changed the entire face construction so there are no welds on the face which creates a 25% larger sweet spot, increasing forgiveness on mis**ts and producing better RBI that the previous welds had a negative effect on. - New ARMRQ Infiniti shaft add's TT1100G to the high mod carbon w/8 Axis weave design.

-

LOOP PROTOTYPE CL Shaft Breakdown

RomaRo Ray V is a damn sexy head, the quality is there, it's workable with forward cg and low spin, shape is really nice too.

-

LOOP PROTOTYPE CL Shaft Breakdown

Shafts can be confusing with the launch of a new shaft brand at TSG I wanted to do things right to make sure people are well versed on these products. Today it's the Prototype CL Shaft - LOOP's hard hitter option. Next step softer is the HD which I will cover in a separate thread. The new CL is their elite players shaft designed with a new tip section technology that takes advantage of Syncagraphites UD (Uni-Directional) Materials, this tip structure is designed to help the faster swinging player avoid the left side or a hook by keeping the tip section from twisting instead it pushes through the ball forward. The tip section is normal stiffness with a forward push anti twist design to help create more distance with stability and anti left characteristics while the mid and butt sections are both considered slightly stiff this design is actually deceiving as the shaft weighs about 65g's it feels more heavier and more stable than most 65g shafts providing a heavier than one would expect. Designed for player who wants to avoid the left side, promote a strong fade and is professional or low handicap level. The structure concept is designed around a lower ball flight and reducing back and side spin while near impact there is less toe drooping. It's produced using a double hold process which is an original technique by syncagraphite's factory. This Loop Prototype CL Driver Shaft is available in 5 Flex options which all above 64-65g in weight ( SR, S, SX, X, XX ) All LOOP Shafts are Custom Install Only - Not Available Shaft Only. Important - Before you comment read this thread : LOOP

-

LOOP Shafts!

It's called the Bubble Light it's 48 grams in stiff flex. If you go to the 53g range it's called the BW which is probably more what your looking for as the bubble is for seniors and ladies the BW is anti right, higher launching with a softer yet forward pushing tip kick. No they do not make custom shafts this means that when you order a shaft it's made to order they roll it fresh.

-

SEVEN K1 in Black Mirror Finish

We do have some pre finished heads that you can email me for and we can put in any finish/paint/shaft/specs/grips for you and there is no upcharge it's the same 500 + shipping for the K1.

-

SEVEN "REAL PROTO" Red2 Blades

I'll give you the lofts but not FP or Bounce - 50/46/42/38/34/30/26/22 This prototype is forged of S15C.

-

Convenience Store Spy Pics!

I wasn't able to see the woods but while she was buying toilet paper I spy'd a Yamaha RMX Maraging Face #5 iron and a 56* Fourteen RM-21 Wedge.

-

Japan Life

-

A few more SEVEN Putters Added to the Store

A couple more to the proshop today. 1 of 3 Prototype with Fine Mill by GF Standard K1 w/ Polished Sole & Translucent Red Paint

-

LOOP Shafts!

If anyone is interested the driver shafts are 600 and the fairway wood shafts are 420. We start by talking with you about which shaft you and I think would best fit you then we have a custom fitting form we send to the factory manager to see what they advise based on your info. [email protected] I was supposed to test my Ray V with a LOOP today at the range but things got hectic.

-

LOOP Shafts!

Go with the CL - http://www.tourspecgolf.com/loop-prototype-cl-driver-shaft But as mentioned earlier we are doing custom fitting forms for this brand, we want to make sure people get the right shaft as it's a new brand and we are trying to keep the customer satisfaction ratings as high as possible. Also as mentioned LOOP is a bit different compared to other shafts, you may think you want mid 70's but if I gave you a 65g CL and told you it was 75g you wouldn't know the difference. The biggest thing I notice is that the tips kick forward and not in a turning motion also it has a different yet similar sensation to 7D where the shaft feels like it kicks totally different than most other shafts. Yes both worked for Crazy for some time, the 2 shaft companies they were with before are big ones I've been asked not to talk about that. I will say that the last major won for this duo by a shaft they produced was in 2013.

-

LOOP Shafts!

A new shaft company is born - LOOP by syncagraphite and while we originally new about them via word in Japan LOOP shafts have caught our closer attention since trying these shafts at a demo session in Tokyo last month, what was most interesting is how stable and heavy they felt yet to our surprise the specs were actually lighter and softer than the result led us to believe and, for this reason, we knew it would be a great addition to the stable of shafts TSG has to offer. Many shafts use multi-axis weave designs where as LOOP uses a UD (Uni-Directional) Material, multi-axis doesn't require as much care in hand rolling construction as well as the multi-axis weaves have a material called penny-whistle or tin-whistle to fill the many gaps, UD (Uni-Directional) Material is a much more pure and complete carbon with no gaps or fillers it is also stronger and more expensive to produce a more consistent shaft using genuine materials. Click Read More to Continue... Designed by M.Hashimoto - Each LOOP shaft bares the name M.Hashimoto, so you wonder who he is, how about who SHE is! Known as the Jewel of the shaft industry, from her hands countless major victories have been achieved as a 30+ year veteran of the trade who is without a doubt the best at what she does.. as well as a cute little old lady In an industry dominated by men, it's pretty amazing to see a woman with so much insight and knowledge about shaft performance for even the strongest of players. Many shaft companies have tried to hire her and her best friend (a man) not married to each other just long time friends from the very beginning more than 30 years ago, these two stay together and do their best work together. The company that has landed this duo LOOP by syncagrahpite and put bluntly they hit the jackpot and are ver lucky as money alone could not acquire them; all the top shaft brands have tried and the bottom line is if you have these two as part of your team your making damn good shafts no matter what. They are responsible for the best years of so many famous shaft companies it's ridiculous. Both Ms. Hasimoto-san & Mr. Takahashi-san the dynamic duo I like to call them have a combined 60+ years hand rolling shafts with a philosophy of emphasizing accuracy and constant shaft movement minimizing energy loss and this is why they believe their method of hand making shafts using UD (Uni-Directional) Materials is the best. While Multi-Axis provides stability in many directions it is not as strong or pure as UD in it's intended direction you can also lay UD in specific patterns using to cover any extra directions needed although this method is more difficult and expensive to produce it's the way many of the special shafts produced one off for the worlds best players have been made. Another important aspect of the dynamic duo's design philosophy is extreme reproducibility so the player can consistently recreate that same great result over and over again for more both distance and accuracy. One thing I want to talk about that's important is the shaft's presentation, TSG knows the various finishing houses in Japan that do shaft graphics, you may think some brands look great but when you inspect it closer at a macro level the text is fuzzy or the paint is blotchy and even worse chip and flake, not going to name any names but there are a couple of brands that have a more than 30% finish defect rate. LOOP shafts are finished out of the industry and with a discerning eye you notice the quality of their matte finish vs. others or how the text is clear with sharp edges or the metallic flake in the colors is vibrant and not bumpy. Pay attention to the details because they matter. Above a PROTOTYPE shaft in a non-retail color it's so beautiful. Below a shot of Ms. Hashimoto-san preparing prepreg for layering. It's not an easy process; one would think especially a man that hand rolling a shaft is a piece of cake just takes a tiny iron a ruler right? Well, not all designs or hand rollers are the same, there is an incredible range of variation between two different people producing the same design, and this will show up in the CPM's and even the shafts results on the golf course. At more than a couple brands I've had conversation with people while they roll shafts as if it were nothing, then others who are so focused they can't even have you watching them without causing a distraction, so the point is those who are casual with this art produce casual results and all the best crafters I've known are not casual about anything they are maniacal and passionate about what they do as the produce their name. In the second image of this post you can see the UD (Uni-Directional) Material after rolling it's a high gloss look after that the shafts are ground smooth and inspected heavily during this process, again and again, this is done to prep the shaft well for finishing a poorly prep shaft not only becomes defective in finish but also performs poorly and on display I saw many major OEM shafts that had unnatural curves to them from well casual workers. The result is total smoothness and consistency, after this, it's further refined via hand sanding and checked over and over for complete roundness by eye/hand/and machine. Below a photo of perfectly round shaft mandrels. LOOP's latest release the PROTOTYPE FW SIX - it's 68 grams in stiff but when testing this shaft I thought it was heavier, with LOOP due to the UD (Uni-Directional) Material and it's designed structure as mentioned at the very start of this post they feel heavier, seem firmer, than what the weight and torque leads you to believe they would play, one common misconception and one of hardest things to dispel from westerners shaft logic is torque/weight/flex you know how it is the guy who should be playing regular is playing stiff, or someone with poor swing mechanics thinks torque is the cure or that two shafts that have similar weight, torque numbers, should perform the same, people this is the wrong way to go about shafts its not only wrong it's preventing the player of finding the proper shaft for their swing ultimately wasting their cash. It's about shaft structure, design, materials and the methods used in making them and, of course, brands don't disclose this information but once you let go of everything you think you know only then are you able to learn new things, I don't know what another way to put this but forget what you think you know about shafts as technology has changed the field and so has various hand crafters. So here is the big question: How do you find the perfect shaft for your swing? That's the million dollar question, right? Straight up it's not an easy thing to do TSG monitors our customers satisfaction ratings of products usually after 45 days of purchase we send our thousands of customers a feedback email to input their opinion positive or negative on their purchase, we see what brands are easy to fit, what brands are hard and what brands produce the best results. Success rate & Failure rates are important to us. You can buy the wrong shaft from a company that makes your perfect shaft and not be happy so what TourSpecGolf is doing is working together with LOOP to produce a fitting form that we send to LOOP for the advice of their factory manager in regards to fitting this greatly increases your chances of finding the best shaft within the brand for your type of swing.... just don't exaggerate on the fitting form please there are so many 200lb 6ft tall men who hit it no more than 220yds due to swing mechanics who would rather claim to hit it 280 for their ego. That will mess your fitting form up. Remember forget what you know so you can be open to learning something new. (above) The shaft oven! (below) Ms. Hashimoto-san working her magic. So I hope you enjoyed this brief introduction of LOOP by Syncagraphite for the next couple of weeks we will be highlighting the brand shaft model by shaft model not just tossing out a ton of options for you to gloss over we will talk about each shaft in an individual post who that shaft is for and what type of player should be using it, beyond that in the TourSpecGolf Forum we will be running a LOOP Custom Fitting Thread to help players see and learn more about what models have worked for others or not. Enjoy the rest of our photos and look for the continuation of our LOOP coverage coming later this week!

-

The Story of Yuji Numazawa - Armsgain

-

Crazy Shaft equivalent?

Don't listen to their website, we are putting something together it's just crazy is taking forever on their end. There is no equivalent shaft to the EVO TS even if you matched weight, torque, flex, cpm's two shafts especially as different as these will play nothing alike. will get back to you on this.

-

Kamui Works KM-300 Custom Spec Driver

Hey Dale, no I dont think so.

-

Honma Beres S-05 Faiway Wood | 4 Stars ****

Usually 4-Star's = a very gold head. That's not how we do it at TSG. Stealth is key here both in head & shaft paint. Honma Beres is for the slower swinger, tour world for the playa, and BeZeal sit's in between. **** = high ton carbon + TT1100G + 8 Axis + Honma rolling it at Sakata. The skinny in the blog, the photos over here: