Everything posted by TourSpecGolfer

-

Miura ICL-601 Driving Irons

Miura does not manufacture this head. It's made in Taiwan and finished in Japan so no I'm sorry.

-

Miura ICL-601 Driving Irons

There is the same custom bending TSG offers on it's irons I believe. 2* either way loft and lie.

-

Got Reviews on the JBeam TF-UT

I'm putting together a short review on the TF-UT one of the best forgiving utilities I have ever tried. I wanted to know if anyone else here has tried it and kept, or moved on.. positive and negative is appreciated!

-

KYOEI Blade Pics!

Wedge is next and CB after that sir. I am pushing for a retail price decrease as well. If all works out these will have a $1000 msrp soon!

-

Ryoma Maxima Pass or Fail?

I expect a fail from the forums being that many of you guys swing hard and fast. But the overwhelming consensus from our online store customers has been awesome. The new Maxima seems to stay in the bag of the smoother tempo player for far longer than any other drivers. Fast swingers thats a different story but thats not to say it isn't possible to setup a build to make one work. the Ryoma Maxima Type-G, it has been out for some months now so we needed to write a review based on my own personal experiences with this club along with the plenty of client feedback we have received from those who have purchased it. First things first though, These maxima’s have quite the line up and it can get confusing so after the jump we will explain the differences between the Type-V/D/G and special tune models Lets start with the old Maxima, it is called the D-1 Maxima and it is no longer produced. The new model as shown here is simply called the Ryoma Maxima and it was 3 years in the making after the previous D-1 Maxima. There are a total of 3 basic versions of the Maxima. Type-V is the black head that is heavier with a square face angle. The Type-D is the silver head which has a closed face angle and lighter head. The Type-G is also with a closed face angle and an even lighter head making it the best choice for the slower swinger. Then there is the special tune which is the non-conforming model which is offered in Gold, Silver, and Black. With the special tune all the heads have the same spec with a closed face angle unlike the conforming model where each version has its slight differences. TSG can also custom order head weights if the player needs something specific for a build. The company Ryoma is very different than other golf brands out there they come from the medical science industry and beat to a different drum than other companies. They spend a lot of time on patents and producing new materials and technologies. What I have noticed is slow to average swing speed players do the best with any of their three models. My wife has been playing Type-G and D for many years and all 3 versions of the Maxima since they were released years back. These have given her much more distance as the spin rates seem to help smoother tempos get the ball up easier popping off the club face hotter. Ryoma says their new face on average when compared to the most popular drivers in Japan such as XXIO and Maruman has 3.8mph faster initial ball velocity speed yet with -900 rpms less spin. It’s a forged cup face but the material is proprietary that no other brand can use. Ryoma calls it Ti TX II. User feedback from customers is excellent with slower swingers. I will say that players above 100mph in that 110mph range could use a head with less spin and a lower launch. The only people getting rid of their Ryoma’s are in that hard hitter athlete segment and they pretty much all order the Type-V. The complaint we see from hard hitters is always spin and direction related. No matter how much Ryoma says the Maxima is also for professional and advanced players we do not see that. What we see is average to slow swingers who fall head over heels for the Maxima more than anything else. The only type of strong players we see get along with the Type-V are those who have better understanding of their own swing mechanics. People with 3800 spin at 105mph+ with an over the top slice or a snap hooking problem are likely not to get the best results from this driver. Everyone else on the slower side of that has been in love with the Maxima’s performance. I am one of those with too much spin and I launch the ball too high so the Ryoma is not exactly my cup of tea out of the box. I have spent years trying to find the path to tame this beast and have had great results with heavier more stable shafts that have a medium stiffness tip section ( FOR ME ) This helps me hit it lower, it helps my tempo with the heavier shaft. I go to the lowest loft Type-V, play a shorter length and heavier head. It’s just about the longest driver I have hit when I slow down my swing and keep my tempo in check. BEYOND POWER – Ok so many people swear by these shafts. Ryoma will not sell the shaft alone or people would be putting these in all sorts of other brands clubs. Beyond power is basically a one size fits all approach to flex. They play softer and lighter and recently Ryoma has released the beyond power plus which is for those that have a slightly faster tempo. The standard BP shaft should be for those who play R2-SR while the plus would be SR-Stiff ( my opinion ). By far we are finding it much easier to fit people into beyond power shafts than Ryoma’s standard tour AD shafts and even aftermarket shafts. I have asked countless times to be allowed to purchase BP shaft as our customers want them in every club after experiencing them. No luck. Thats pretty much my take on the Type-G and who I feel it is best for. To summarize everyone with a slow to average swing speed & tempo loves these. Average players, women, seniors are all getting more distance and consistency from the new Maxima’s. Stronger players should go with the Type-V and Beyond Power Plus shaft. If your over 105mph we suggest a custom build with an aftermarket shaft.

-

Honma TW-PT Putters!

Honma fans will be happy with this release finally a tour world series mallet with a simple yet stealth shape and theme. I say stealth because it kind of reminds me of one in black. Honma did a lot of testing with their professional players narrowing it down to a couple of shapes they really liked. Lets sort what it is first. It’s made of forged stainless steel that has been cnc milled. the sole panel itself is made of Aluminum while the weights are made of tungsten. You have two fourteen gram weights to increase the MOI. These are not adjustable weights. This mallet is obviously center shaft which most people believe aids the golfer who has the more straight back and through stroke with less arc. The face is milled deep for a soft feel. The head is finished in a matte subdued black. Honma did a great job on the shape. You can see they were very particular about all details and aesthetics intentionally leaving the mill marks not choosing to polish them off, everything seems intentional and well thought out.

-

KYOEI Blade Pics!

-

The Benock Putter Thread!

Pics of the prototype SEVEN X BENOCK putters. We are a couple months out from releasing the final models. All of which will be mallets!

-

Off the rack Mizuno brand golf clubs in Japan are going away?

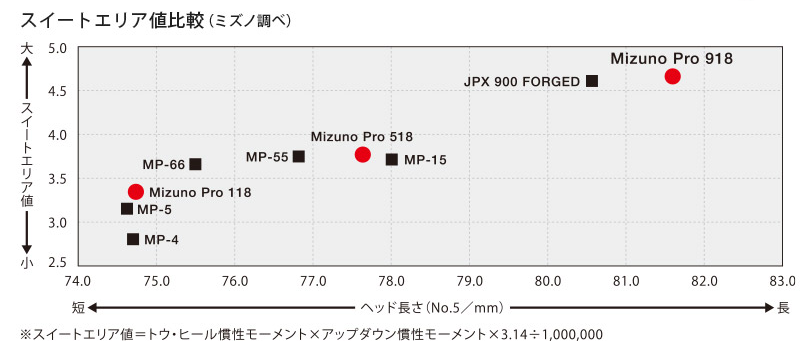

Yes that is correct they plan to only sell through in person fitting dealers. TSG will be selling these as well not a problem. Mizuno does not sell well in Japan. The shoes yes but clubs not really. I find it funny that some brands are moving toward the past instead of the future. Doubling down on the retail sales model and pulling back from the web is very cave man. The exact opposite is happening in nearly all industries as malls are closing, brick and mortar anything can't compete, golf shops can only do volume at a huge expense while the brands that they bow to also deal directly to the customer now... btw multi layer finish is like NICR Satin like a seven putter. Here is where the 118's sit. Nob's care to explain this chart?

-

The New SEVEN MCB

- Seven MC-Bliss

Top Line Photos and Sole Pics. While the M stands for Medium this iron has a thin top line with offset is like a blade. The cavity is very deep for its size. The leading edge is pronounced. The sole and the shape are the reason why the MCB is so easy to hit.- Miura ICL-601 Driving Irons

You and I are in the same boat. Left shoulder injury took almost a year to heal, then I got chronic plantar fasciitis and bicep tendonitis... after rehab, shots, steroids and plenty of time off.. I finally got better and I was cleared to work out again. Hurt my other shoulder 2 weeks later. My sport hobbies do not help. I am slowing the swing and playing lighter softer shafts now days.- Seven MC-Bliss

Great to hear! Thank you for this review. All SEVEN MCB's are sold out as of today 7/18/17. It will be another 2 months before we get more and during those 2 months the back order will grow. It is likely we will be sold out before they arrive. This direct to consumer stuff is working. I doubt we would be selling as many if the head price was $600 ea.- The Benock Putter Thread!

Anything you want and you can even create your own options. It gets pricey but no one can touch Benock.- Pics of the new Crazy CRZ Full Titan Fairway Wood

I use both, and the modart MA01F. I like how the modart goes straight and makes nice turf interaction. It also has a low spin and low launch tracjectory. It's really nice with a heavy shaft with softer butt section for my swing. The Ryoma is longer, more comfortable for me off the tee, works very well with a nice heavy 75+g fairway wood shaft. I especially like it in a 5 wood. 3 wood is important for me on long courses. not workable but straight, spins higher than the modart and crazy. taller trajectory. Crazy full titan is if the modart and ryoma had a kid. I love everything about it but the shallow face that makes it easy to get airborne is also what I wish were a bit taller in height.- Miura ICL-601 Driving Irons

I am told that he uses one that performs very similar to the new TW-U. - https://www.tourspecgolf.com/japanese-golf-clubs/honma-tw-u-forged-utility-iron.html- Miura ICL-601 Driving Irons

They are cast, made in taiwan yet perform really nicely. The ICL-601 by Miura Golf was just announced and released in Japan. Its a driving iron with a hollow cavity and weight screw located on the sole. Miura designed this club as an optional replacement to the long irons in their forged iron sets creating a club easy to hit 200 yards and beyond. First thing to note is that its a driving iron and how that differs from a hybrid is the DI is basically a really forgiving long iron and in this case it is a hollow structure made of SUS304 in the body with a 455 carpenter steel face which is commonly used in fairway woods. The standard weight screw is 8g but Miura does offer optional 4/6/10/12g weights to help you dial it in. TSG can also custom order the weight you desire already installed at the factory. This head does have a good amount of offset but that is usually necessary to help square the club face up and hit straighter shots. If they went ahead and made this a straight neck it would be so much harder to hit than it is. The top line and shape is very attractive from its wide flatter sole to its clear blade top line all done in brushed satin to reduce glare. The CG is of course deep considering the weight location but also this head when hit was very tolerant of mistakes. On the grass range the consistent straight and medium / high ball flight was evident. I feel many Miura forged iron players should drop their long irons for one of these. Those who hit long irons better than hybrid woods should use a driving iron. Its flat sole with little bounce and camber makes perfect entry in dry or wet conditions. A little camber may be needed if you play in soggy conditions but its light years easier to hit than most 3 & 4 irons. Miura did not make this in Japan and they were very transparent about it being made at their Taiwan supplier. Because this head is made of steel there is no finish or plating its brushed as a SUS putter would be. Miura is offering 3 lofts 18/20/23 all 3 are heavy with the base weight of 8g at 232/238/244 grams. The Miura ICL-601 comes with a nice carbon look cover. The 23* is now shipping to customers while 18/20 will be released at the end of July 2017.- Korea Only Gold IP SEVEN CB!

We can mill from raw sandvik or even use forged stainless. Those two options would not feel better than the forged S20C currently used. We tested SS400 also and while it was the softest it was not very durable and the loft would bend quickly. We removed the heat treatment from CB and MCB in the 2nd and 3rd production runs because we could not tell much of a difference and due to lead time and extra cost.- The American Classic Remastered – MacGregor IM-G5 Classic!

Mactec was a line in Mcgregor line up. They are still around.- USA Exclusive Model – SEVEN CB in Black IP!

Introducing the USA Exclusive Finish for the SEVEN CB – BLACK IP! Last week we posted the Korea Only GOLD IP exclusive (click here). Today we are highlighting our BLACK IP finish which will only be sole and shipped within the United States. Based on our more than 15 years in business its evident that American golfers gravitate to black finishes in their blades and cavity backs. This finish here is very durable and will not rust. The standard NiCR chrome finish is first applied then we send the heads into a factory for the Black IP treatment which bonds with the clubs original plating. The wear pattern will expose the standard finish in areas that make impact with the ball or turf. From above the SEVEN CB is one of the most beautiful players cavity backs on the market. In it’s black finish it looks even more dark and stealthy. From its full face milling to its CNC milled grooves the SEVEN CB and MCB are the highest quality irons made in Japan today and this Black IP finish is no different. When comparing various finishes such as IP, DLC and others It is evident that Japanese IP and DLC is far better than the same finish applied by Chinese factories. For your reference SEVEN will never produce anything in China and every process and material originates and done 100% in Japan. In our testing we found no difference in feel hitting the Black IP against the standard finish. The SEVEN CB is extremely forgiving for it’s size we believe it is the most forgiving 1 piece forged players cavity back to ever be made and furthermore it is very soft and addictive at impact yet not gushy. What you are looking at here is pure quality that represents the very finest Japanese manufacturing can achieve. Today on the PGA tour there are roughly only 3 players who use 100% CNC milled irons, RORY, ROSE, and D.Johnson all Taylormade Prototypes. Those are not made in Japan and do not have the same angles of milling. Brands such as PXG’s milled wedges and Taylormades RORS prototypes still show milling done in a circular fashion. You are now able to play full CNC irons made at a higher quality than even the best players in the world. We are now taking reservations for both the Korea Exclusive GOLD IP Seven CBs and the U.S Exclusive Black IP finish Seven CB’s.- The American Classic Remastered – MacGregor IM-G5 Classic!

Introducing the MacGregor Japan Tourney Classic IM-G5 Iron Master Putter! This putter is 100% made in Japan as a limited edition based on the original dating back to the 1930’s when it was named after Tommy Armor. Back in the 30’s to 40’s it cost only $8.00 brand new oh have time changed as today it costs almost $600 dollars. Back in the day there were three versions · IM straight neck · IMG gooseneck · IMGN Swan neck The number after the model name represents the length. IMG 5 → 35 inch. IM stands for Iron Master while the G stands for gooseneck. Players who play L style putters use them to avoid the left side. This head is 100% CNC milled of stainless steel in Japan. The quality is beyond anything MacGregor golf has ever produced. The heel weight is made of SS at 10 grams while the toe is 19 grams made of tungsten to promote a straighter roll. Its body is made of SS400 an extremely soft Japanese steel while the face milling has a cool wave effect to promote straightening of miss-hits. It comes with a wrench yet no extra weights ( sold separately ) It comes with a leather head cover along with a special Microfiber grip (69g) made by Muzik Golf. The putters shaft is the heavier 136 g “NS Pro” made by Nippon Shaft Co producing a stable stroke with moderate weight sensation. Its such a beautiful and well made putter and having putt with it myself I can say with confidence it is the best iteration of any L shape putter to hit the market to date. These will go quickly and TSG only has several in stock. You may purchase by ( clicking here ).- The New SEVEN MCB

I am going to take all of your phrases to describe golf clubs from now on! - not unlike my farts - dense spring - sea sponge - cottage cheese with chives - unmelted candle wax - rubber on the rocks I love it thanks! Expect a royalty check for use of your IP.- Mitsubishi OTi new release .355 taper

Yes OT Tour is taper tip. I am excited about these but I have just recently tried the OT105 and like its smooth feel and noticeable kick. My assumption is that these new OTs will have a stiffer tip and be closer in profile to Fuji MCIs. October release though guys.- Korea Only Gold IP SEVEN CB!

Each country will get their own exclusive models.- The New SEVEN CB

Yes for the states the exclusive model is Black IP ! - Seven MC-Bliss